product

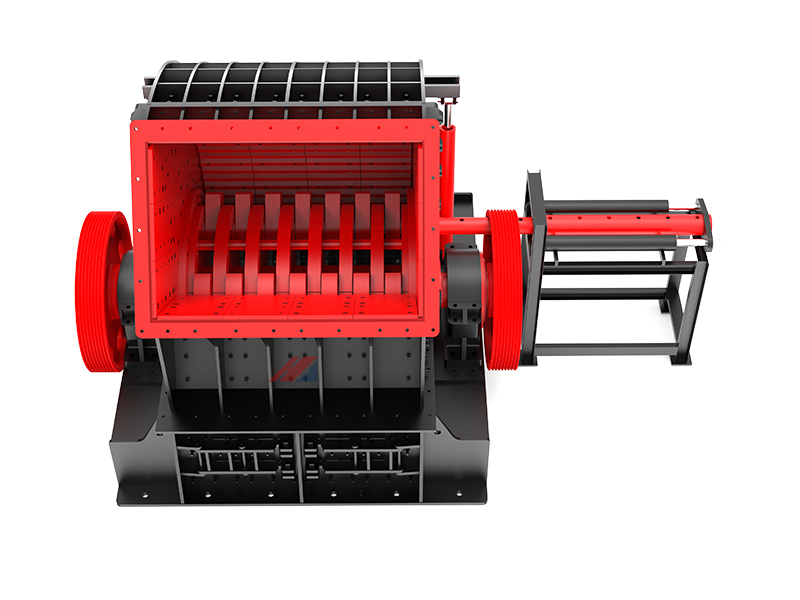

The PCZ series heavy hammer crusher is a new type of heavy hammer impact crusher developed based on traditional hammer crushers, incorporating user feedback and industry developments. It is suitable for materials with a feeding size up to 2 meters, a compressive strength ≤200 MPa, and a calcium content ≥40%, such as limestone, ordinary sandstone, and construction waste. It is used in industries like mining, cement, building materials, and chemicals. It offers advantages such as large feed size, high crushing ratio, high yield, and a rounded particle shape. For production capacities below 600 tons per hour, it can produce general-grade aggregates directly (high-grade aggregates require secondary crushing).

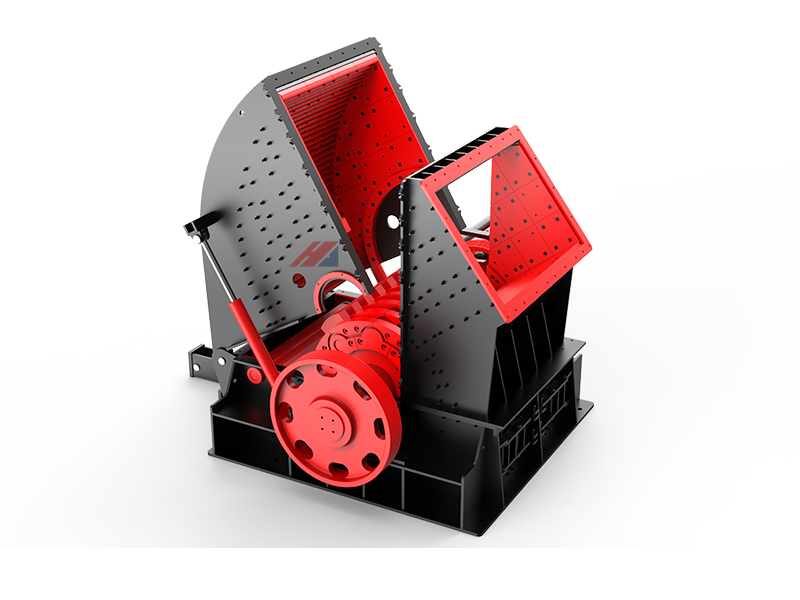

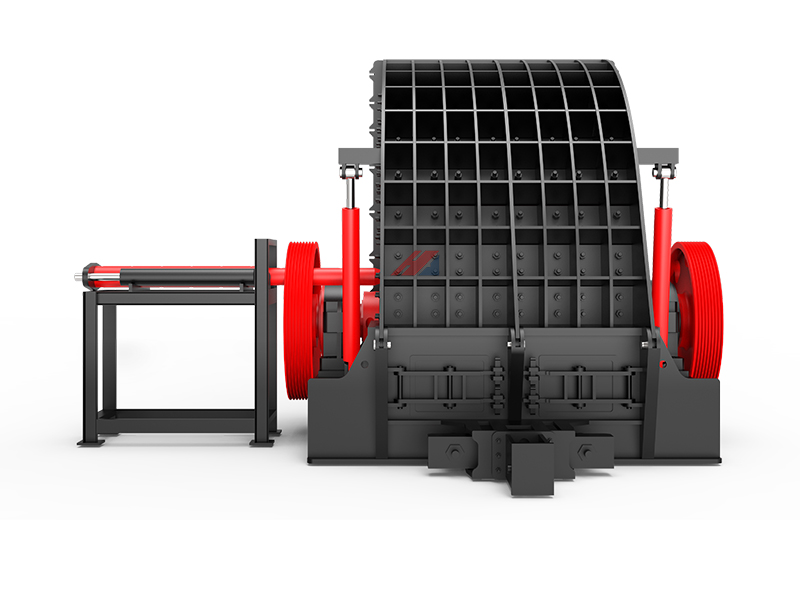

The new model features hydraulic opening for ease of maintenance. The hydraulic system adjusts the gap between the impact plate and rotor, allowing for flexible control of the discharge size. The larger chamber design enhances throughput and increases the crushing ratio and yield.

It can handle a maximum feed size of 2 meters and achieve a single-machine output of up to 3000 tons per hour. The absence of grate bars increases material throughput and allows for crushing of wet materials with moisture content up to 15%, solving problems of small feed size, clogging, and low yield in traditional hammer crushers.

For capacities up to 600 tons per hour, it produces general-grade aggregates directly (high-grade aggregates require secondary crushing). It replaces both jaw crushers and impact crushers, enabling a simple single-stage process and reducing investment by approximately 35% compared to a combined jaw and impact crusher setup.

Materials are subjected to three stages of crushing, resulting in cubic-shaped particles that meet national standards for construction materials. The hydraulic adjustment and self-flow chute design minimize repeated crushing, reducing the amount of fines produced.

The unique rotor disc with a full-wrapped wear-resistant ring overcomes the issue of severe wear and manual hardfacing in traditional designs. The wear-resistant ring is fixed with fasteners and is highly durable and easy to replace. The hammer disc is designed with eight hammer shaft holes, with four spare, significantly extending rotor disc lifespan.

The hammers are made from advanced high-chromium alloy with a double-liquid composite design, offering high impact resistance and wear resistance. This extends the replacement cycle, reduces downtime, and increases production capacity.

The rear shell features a reinforced structure with high-strength bolts and disc springs for stability. The interior is lined with four different styles of wear-resistant plates fixed with high-strength bolts, and industrial felt underneath to cushion material impact, ensuring the shell remains intact and unaltered. The hammers can rotate 360 degrees, with large individual weights and disc diameters, allowing resistance to large material impacts. The optimized design eliminates grate bars, reducing hammer wear and extending lifespan by 3-5 times.

The crusher can be customized to produce different sizes of aggregates, such as 3-8, 4-8, or 5-8, based on specific requirements.

| Model | Rotor Spec(Dia*L)(mm) | Feeder Opening Size(W*L)(mm) | Max Feed Size(mm) | Capacity(t/h) | Motor Power(kw) | Overall Dimension (mm) |

| PCZ1310 | 1310*1050 | 890*1075 | ≤650 | 150-180 | 160 | 2950*2250*2495 |

| PCZ1512 | 1500*1160 | 1200*900 | ≤750 | 250-320 | 160*2 | 3260*2624*2750 |

| PCZ1513 | 1500*1350 | 1290*900 | ≤750 | 300-350 | 180*2 | 3260*2624*2750 |

| PCZ1615 | 1650*1452 | 1500*1200 | ≤1000 | 420-500 | 220*2 | 3667*2937*3436 |

| PCZ1815 | 1850*1520 | 1500*1280 | ≤1100 | 520-620 | 250*2 | 3680*2915*3515 |

| PCZ1620 | 1660*1900 | 2000*1200 | ≤1200 | 800-1000 | 400*2 | 3667*3200*3436 |

| PCZ1820 | 1800*1964 | 2000*1200 | ≤1200 | 1000-1200 | 450*2 | 3700*3270*3515 |

| PCZ2225 | 2200*2485 | 2530*1560 | ≤1600 | 2000-3000 | 1250 | 4460*4565*4670 |

| PC0706 | 700*570 | 618*510 | ≤400 | 50-70 | 75 | 1950*1340*1480 |

| PC0808 | 800*750 | 780*610 | ≤500 | 80-100 | 132 | 2280*1790*1670 |

| PC0910 | 900*1000 | 1070*750 | ≤600 | 150-200 | 110*2 | 2600*2200*1940 |

| PC1012 | 1000*1180 | 1255*810 | ≤650 | 250-300 | 132*2 | 2800*2310*2210 |

| PC1213 | 1200*1280 | 1350*920 | ≤750 | 300-350 | 160*2 | 2970*2580*2510 |

| PC1216 | 1200*1590 | 1530*920 | ≤750 | 400-500 | 200*2 | 3070*2840*2580 |

| PC1220 | 1220*1950 | 2000*920 | ≤750 | 500-600 | 220*2 | 3080*3380*2580 |

| PC1622 | 1620*2200 | 2200*1000 | ≤900 | 600-800 | 250*2 | 3695*3250*3450 |