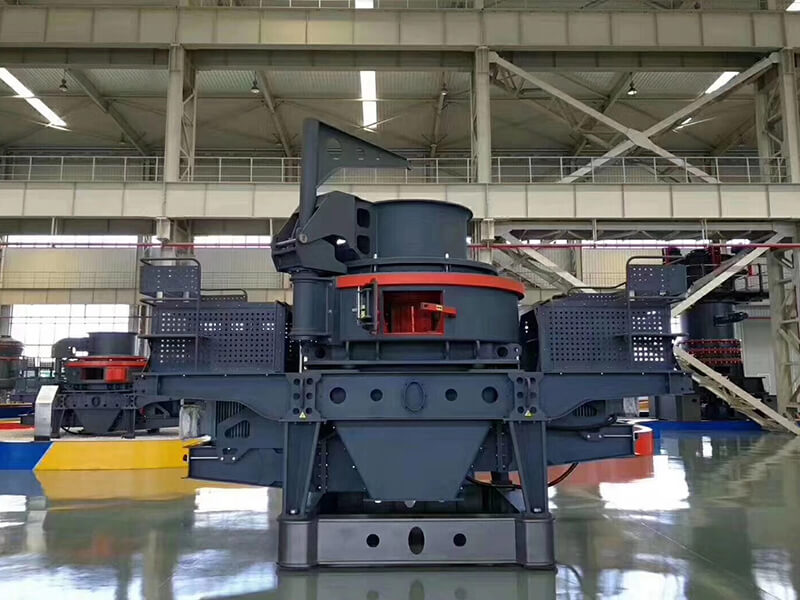

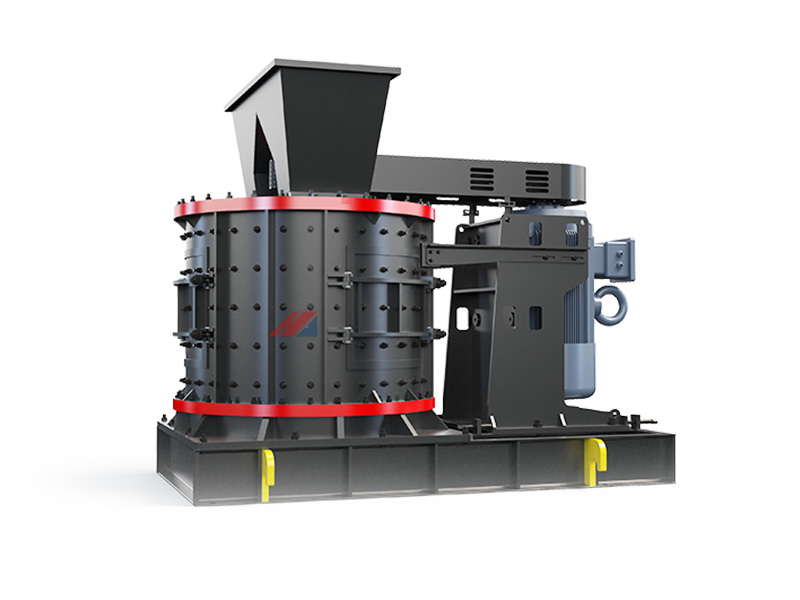

Marble is an important construction and industrial material. Natural marble cannot be used directly and needs to be processed using equipment like the marble sand making machine from Shanghai Hengborui. Here are some common issues that may arise with sand making machines:

Excessive Vibration The marble sand making machine should operate relatively smoothly. Although marble materials can impact the equipment significantly, modern machines are designed to handle such impacts. Excessive vibration can result from long-term wear, excessive feeding, or the presence of high-hardness foreign objects in the feed. In such cases, it is necessary to replace worn parts promptly, reduce feed particle size, and strictly control the feed to ensure no high-hardness foreign objects are present.

Coarse Particle Size of Finished Sand If the particle size of the finished sand is too coarse, it may be due to loose V-belts. In this situation, the V-belts should be tightened immediately. Additionally, wear of the internal screen mesh of the marble sand making machine can also lead to coarse finished sand. The screen mesh should be replaced promptly, and the condition of the screen mesh should be checked before each operation.

Overheating of Bearings Overheating of bearings may occur during the operation of the marble sand making machine, primarily due to lubrication issues. Check if the lubrication is adequate and if there are any impurities in the bearings. Clean the bearings if necessary. Long-term wear can also lead to bearing overheating. If bearing wear is detected, it should be repaired promptly. In cases of severe wear, bearings should be replaced immediately.